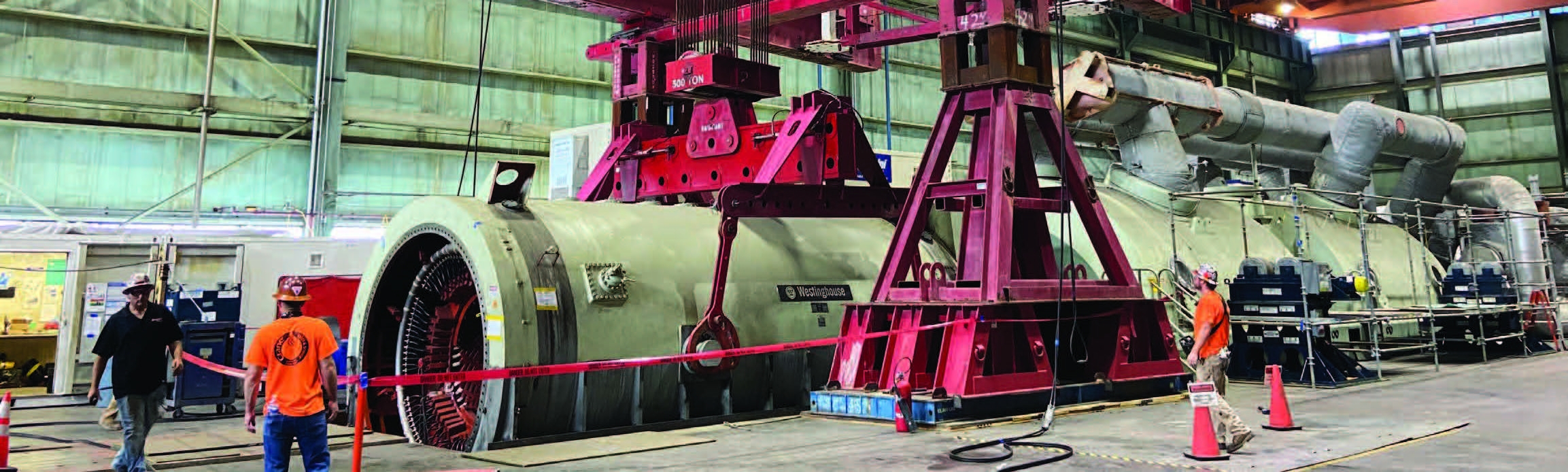

Barnhart was contacted by a customer to remove and replace a failed stator at a power plant in Missouri that required a rapid deployment. At the site, the crew used a modular lift tower (MLT) plus a 500-ton hoist to lift the damaged stator. Two 120' runs of 8' girders supported by 600-ton gantries were required to span from the pedestal support to crane bay supports.

The stator was then loaded onto a 16-line Goldhofer PSTe trailer and transported to an on-site staging location. Meanwhile, the replacement stator was coming from a decommissioned plant in Louisiana, which was 700 miles away. It was identical in weight and dimensions: 720,000 pounds, 40' long, 14' tall and 15'4'' wide.

In Louisiana, however, poor soil conditions had to be addressed before Barnhart was able to set up its MLT. The replacement stator also would not fit through the crane deck and had to go through a wall opening 46' in the air. A 500-ton hoist was used to lower the stator onto a Goldhofer trailer. It was then loaded onto a 24-dolly transporter for the trip to the rail spur.

Seven hundred miles later, the replacement stator was successfully delivered to the Missouri site to replace the damaged stator. While a typical timeline for this work is 12-18 months, Barnhart successfully finished within a three-month timeframe. This helped the customer avoid potential grid disruptions during the peak summer season. This project was awarded an SC&RA Rigging Job of the Year Over $2 Million.