Every component in every plant has a finite lifespan. It's a fact all industries have to live with. When a heavy component needs to be replaced, whether due to failure, plant modification or expansion, the challenge is to remove the old and replace with the new in a manner that emphasizes safety while minimizing plant disruption and downtime. Often, space constraints make equipment removal all the more challenging, requiring the entire logistical process of lifting, removal, transport and replacement be exceptionally well planned and coordinated.

This is where Barnhart excels. We specialize in providing innovative solutions for both equipment removal and equipment replacement for tough-to-reach plant equipment in congested industrial sites. Barnhart has developed unique custom tools that allow our network of professionals to create solutions that best optimize project schedules and manage costs. In fact, over the past four decades Barnhart has developed specialty rigging techniques and equipment that have revolutionized the way components can be lifted, upended and transported - safely and efficiently. And we have done so for a broad range of industries and a wide variety of plants.

Barnhart's vast experience and expertise, along with our rigorous safety standards, assure you of the most efficient and cost-effective component equipment replacement during an outage, shutdown or turnaround. As one of our customers put it: we make the impossible, possible.

Barnhart's vast experience and expertise, along with our rigorous safety standards, assures you of the most efficient and cost-effective component replacement during an outage, shutdown or turnaround. As one of our customers put it: we make the impossible, possible.

Save Time and Money

Sometimes the "way we've always done it" isn't the fastest, most cost effective or even the safest. Check out Barnhart's innovative approaches that might move you from the old way to the best way.

Minimize Disruption

More cranes, more people, more equipment usually doesn't just mean more money. It also usually means more interruption. Our ideas seek to minimize or eliminate disruption to normal operations at your site.

Innovative Solutions

By involving our engineers and rigging experts early, Barnhart develops custom solutions that can save you time and money. Early involvement often allows us to see options that others can't and create innovative solutions that may not be at the back-end of a project.

Barnhart Toolbox

Barnhart gives you access to custom-designed and fabricated specialty rigging that cannot be found anywhere else — tools specially engineered to safely save you time and money. Barnhart also has one of the largest crane inventories in North America.

Built-in Safety

All of Barnhart's "cool tools" are designed by us with the optimum safety standards in mind. Efficiency and speed are useless attributes without safety.

Network Of experts

Barnhart's 50-person, in-house engineering team are experts in heavy lift and heavy rigging, reducing the need to hire third-party engineering for your project.

Along with our highly skilled technicians and rigorous safety standards, Barnhart's nationwide network of tools empowers us with the unique ability to fulfill your needs better than anyone else. Below are just some of the specialty rigging and crane tools we have access to in order to get the job done.

CC2000 - 330 Tons / 440 Tons

CC2600 - 550 Tons

CC4000RL - 1,760 Tons

Goldhofer PSTe

CC4000

WesTrac/EasTrac

Pull Up Gantry

Moveable Counterweight

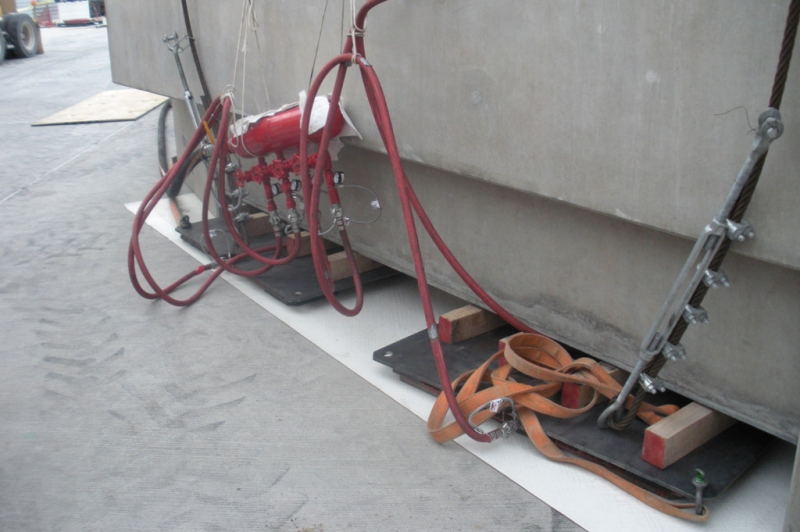

Air Skates

Powered Saddle Rollers

Tip Stick

Hydraulic Gantry

Tri-Block

Modular Lift Tower

Hydraulic Turntable

Hydraulic Skidding System

VersaLift

Twinlift