Barnhart was hired to remove and replace a stator at a nuclear plant in New Jersey. A load test was first performed, which involved the assembly of a Modular Lift Tower (MLT) frame at Barnhart’s Memphis location. The test load weight, including support girders, was 1,332,160 lbs. or 125% of the lift load.

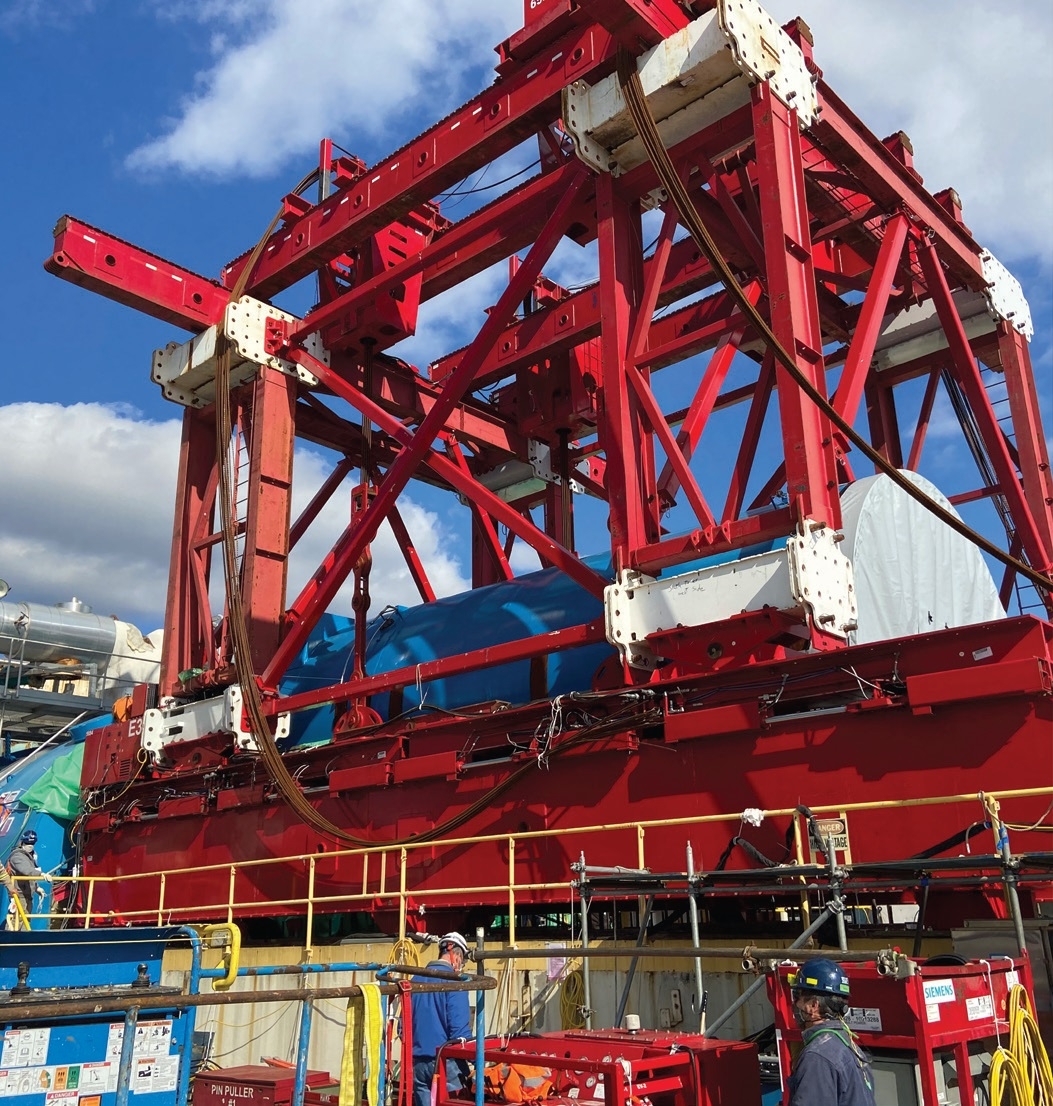

At the site, a MLT, 750-ton hydraulic turntable and 500-ton slide system were used to rotate the stator.

The MLT was tight between two water tanks, overhead gantry crane bents and a turbine building. There was just six inches of clearance between the turbine building and stator during the lift tower operations.

Strand Jacks were utilized to raise and lower the Stator. The project required more than 50 calculation packages, 70 drawings and 650 plus of match-marked components. But the work paid off in a project that was completed safely and without incident.