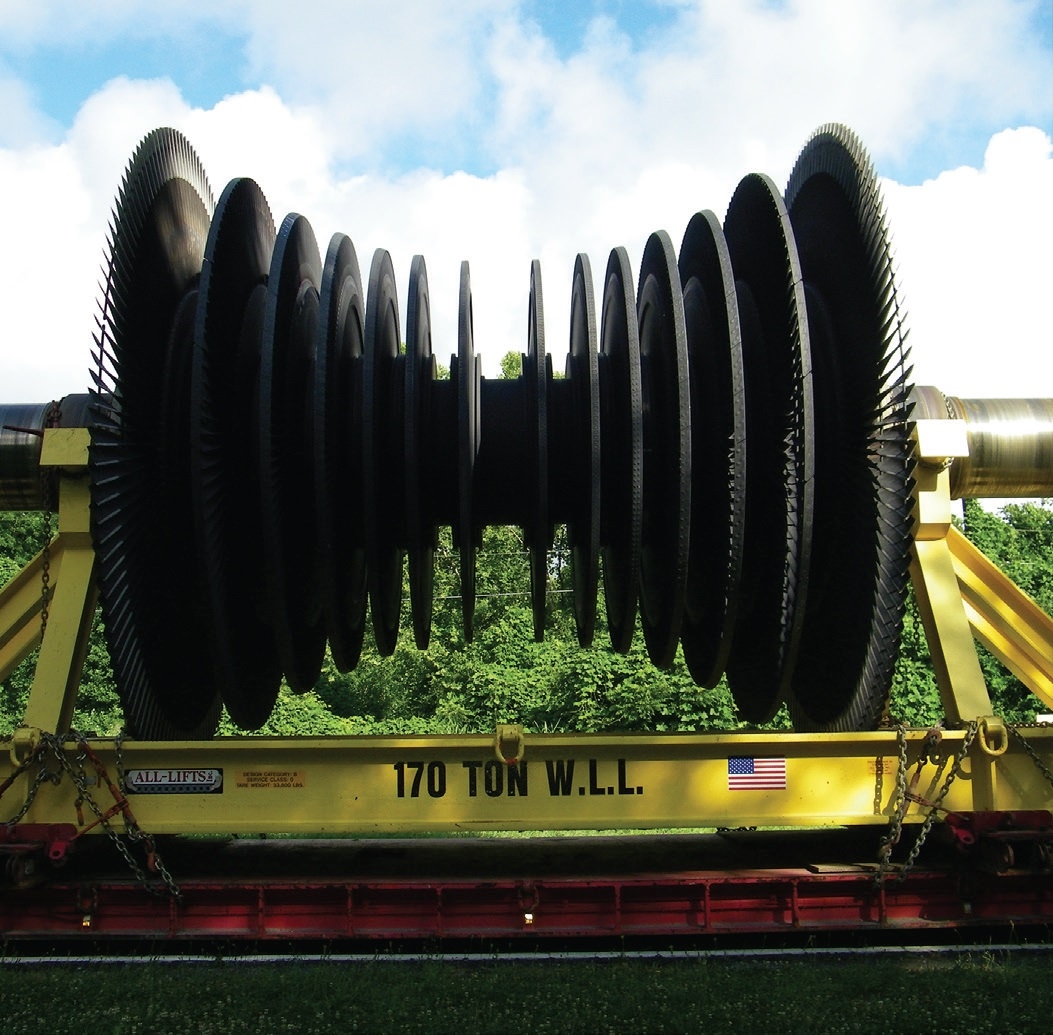

Barnhart was awarded a project during an outage at a nuclear power station to transport, stage and dispose of three low-pressure (LP) turbine rotors and the associated diaphragms. Each rotor was approximately 30 feet long, weighed 365,000 pounds and had a diameter of 15’6”. The diaphragms ranged from 5,000 pounds to 28,000 pounds and varied in length.

Barnhart identified a more cost-effective approach than its competitors for this project. This included sliding the LP rotors on and off the transporter versus handling with a crane or gantry and optimizing to a THP Goldhofer trailer for over-the-road hauling versus using the PST Goldhofer trailer that was required for the onsite hauling. Another approach was partnering with an approved local scrap vendor for disposal.

The team utilized Barnhart’s 500-ton slide system to support the LP rotors on the transporter while in transit. This allowed for a quick and cost-effective means to load and offload at the staging area and scrap yard. As the convoy went through town, utility crews raised traffic lights so the load could safely clear overhead obstacles.

The rotors were hauled approximately 15 miles to a utility-approved scrap and recycling facility just across the state line in North Carolina. They were then offloaded via slide system and removed from the rotor stand with 500-ton one-shot gantries.