Learn More About Remove & Replace

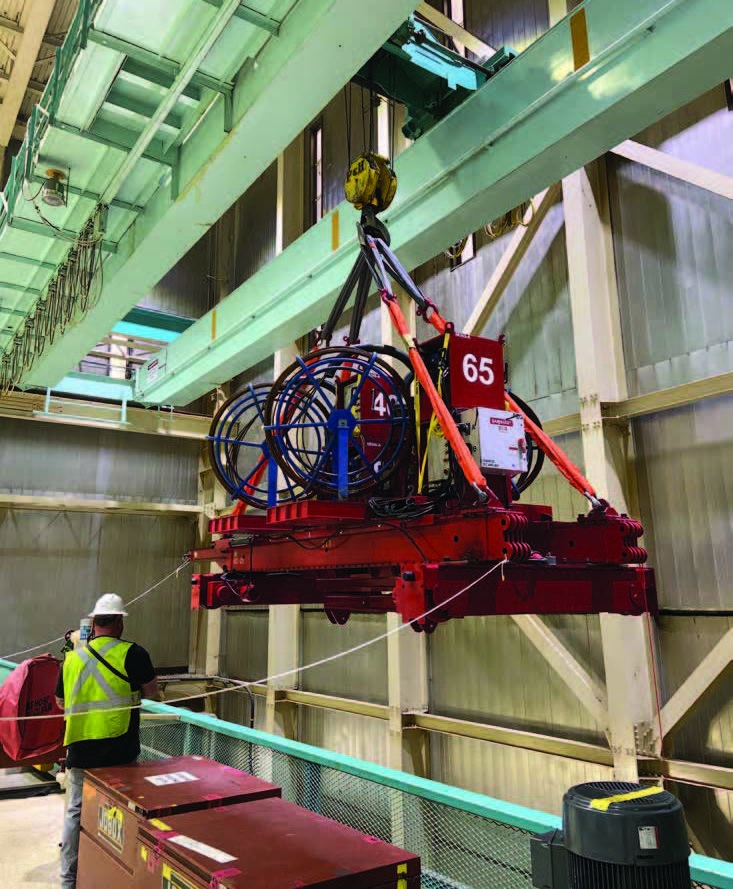

Barnhart devised an unusual way to remove and replace two 130,000-pound feedwater heaters (FWH) at a nuclear plant in South Carolina. They created a custom temporary lifting device (TLD) that used a combination of four strand jacks and a custom-designed Strand Management System. This system allowed lifting without damaging insulation on the FWHs or requiring workers to struggle managing strands over obstructions and from elevated positions.

The area was congested and ground bearing pressure allowances were low. The team used its Barnhart Push-Up Units, a high-capacity system which has a small footprint and excellent stability. The separate synchronized units pushed a turntable and the TLD to elevation. The lifting device was rotated and set on top of the overhead crane rail.

The old FWH was attached to the TLD utilizing a custom swiveling spreader bar. The heaters started in a vertical position and required tailing to a horizontal position for removal and over-the-road transport. There was approximately an inch of clearance available for the final TLD assembly to the roof structures and lifting configurations to clear the lower floor obstructions.

The heaters were lowered onto Barnhart’s 500-ton slide system and custom tailing and sliding saddles prior to staging on the turbine deck. Prior to lifting operations, the team identified and labeled the operational limits of the TLD in the overhead and FWH bearing points on the floor. The engineering and fabrication of these components had to be perfect for all the moving parts to function as one.

The new feedwater heaters were brought in on a trailer and staged on the turbine deck prior to the outage. The process was reversed for the installation. Customer expectations were high, and Barnhart exceeded them by completing the project several shifts ahead of schedule, resulting in time and cost savings.