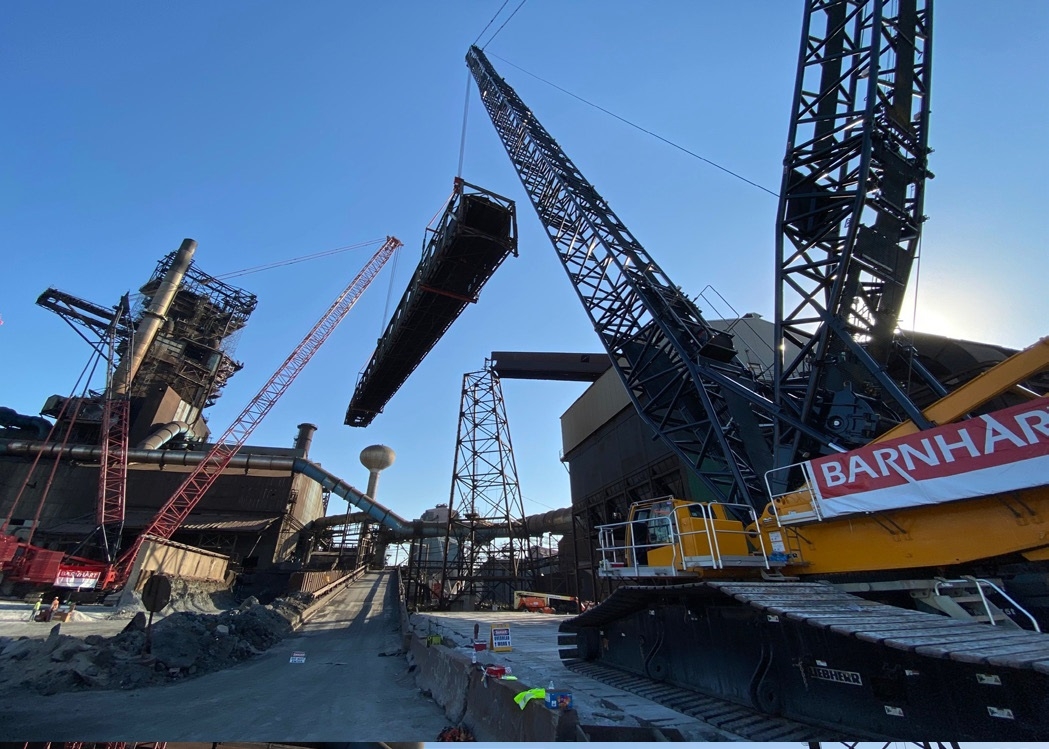

Barnhart was called to a steel mill in Illinois to remove and replace a 320’ conveyer section weighing approximately 600,000 pounds. The crew assembled an LR1600 crawler crane in full super lift with tray and a Manitowoc M18000 crawler crane with full super lift and maxer wagon.

The height of the conveyor was 300’ on the low side and 340’ on the high side. Installing the cradle beam to carry the load using Barnhart’s Movable Counterweight Cantilever System posed a challenge to the team. Once the rigging was assembled, the maintenance contractor removed the anchor hold holding this section. It was lifted up and out.

Using spreader bars, Barnhart made a tandem lift using both cranes at the same time. The conveyor section had to be swung 40 feet to the right to clear the tower.

Once the old conveyor was removed, it was loaded to a 12-Line PSTe Goldhofer and set on-site. The new conveyor was loaded onto the Goldhofer. The process was reversed for the replacement of the conveyor.