Barnhart was called upon to provide logistical and heavy rigging expertise to receive and assemble an $8 million piece of medical equipment, known as a cyclotron, in Knoxville, TN. Given the logistical complexity and space limitations on site, the cyclotron pieces were received at one of Barnhart's local facilities. There, Barnhart assembled the cyclotron into two large sections - 110 metric tons each - which made for faster final assembly at the site. Barnhart offloaded, staged, and then preassembled the sections using its 44a gantry with 200T swivel and a 500T slide system.

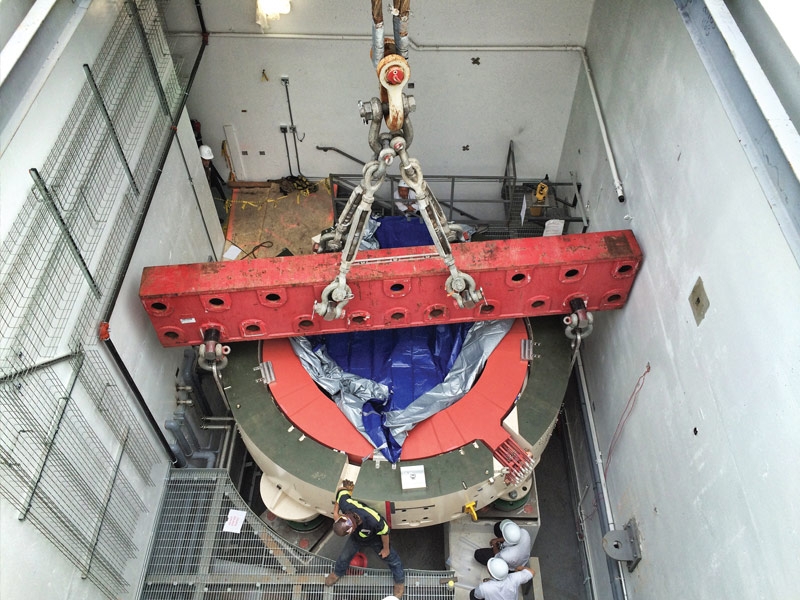

The two halves were then transported on a 12 line 1-1/2 wide SPMT Goldholfer to their destination. There were more challenges at the medical facility. The center of the hatch opening where the equipment was to be lowered was offset approximately 7' to where the center of the cyclotron was to be placed in its final position.

A modified Barnhart Stator Frame was able to lift and move horizontally over the opening, lower and then side shift to required location. Both halves had to be set within +/- 1 millimeter. Equipment included were Barnhart's 200T hoist and an elevated 600T gantry system.